Humanoid Robot Whole-body Geometric Calibration with Embedded Sensors and a Single Plane

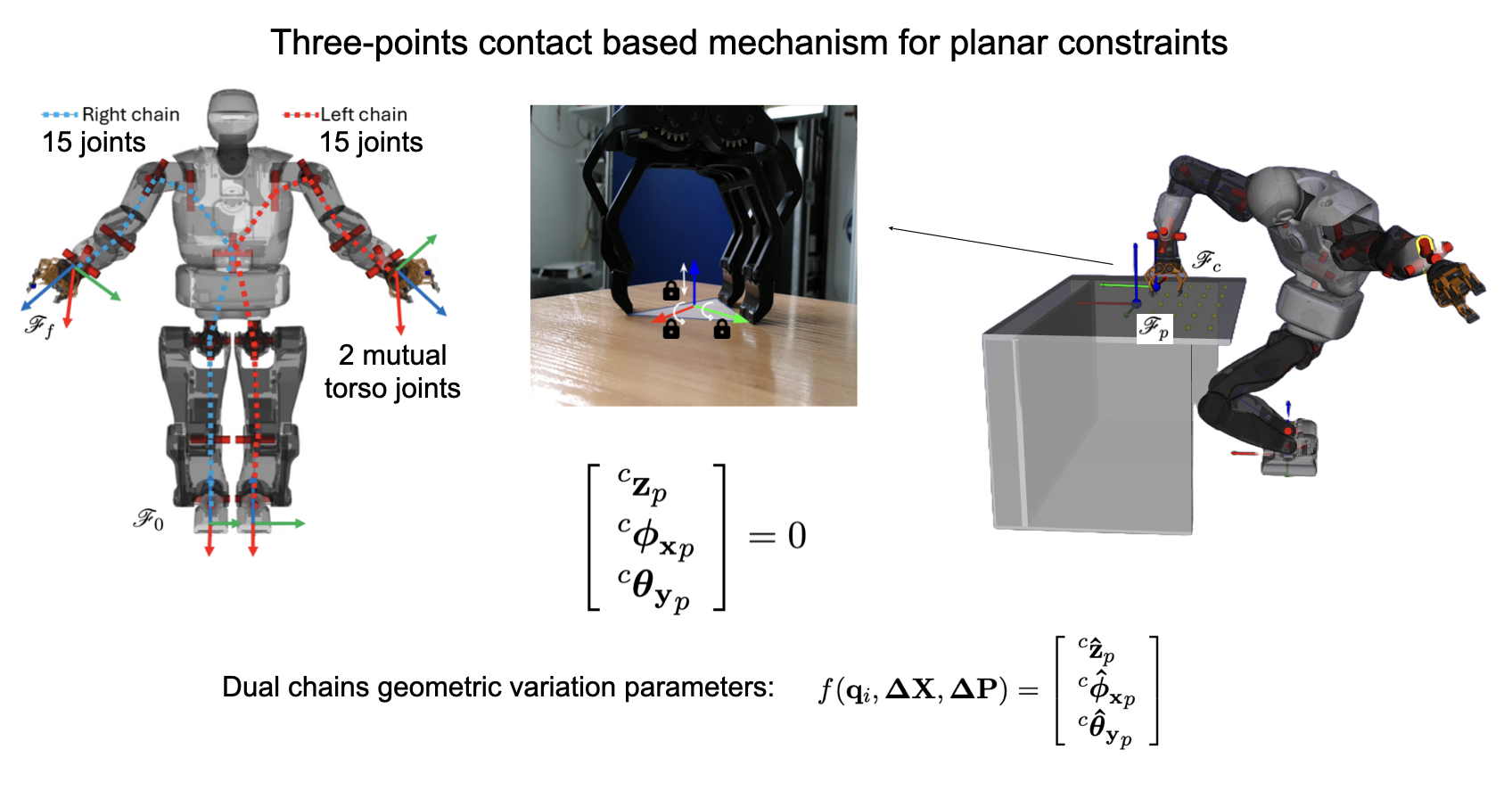

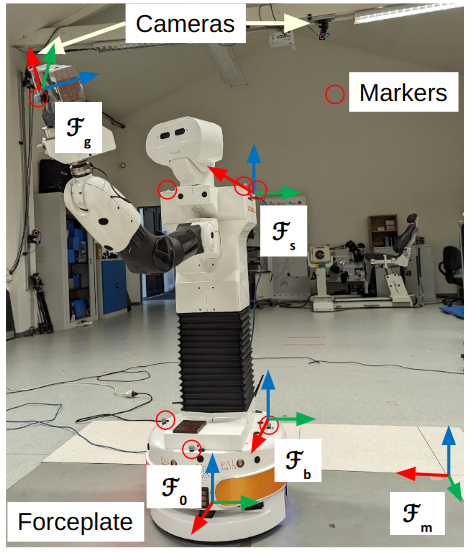

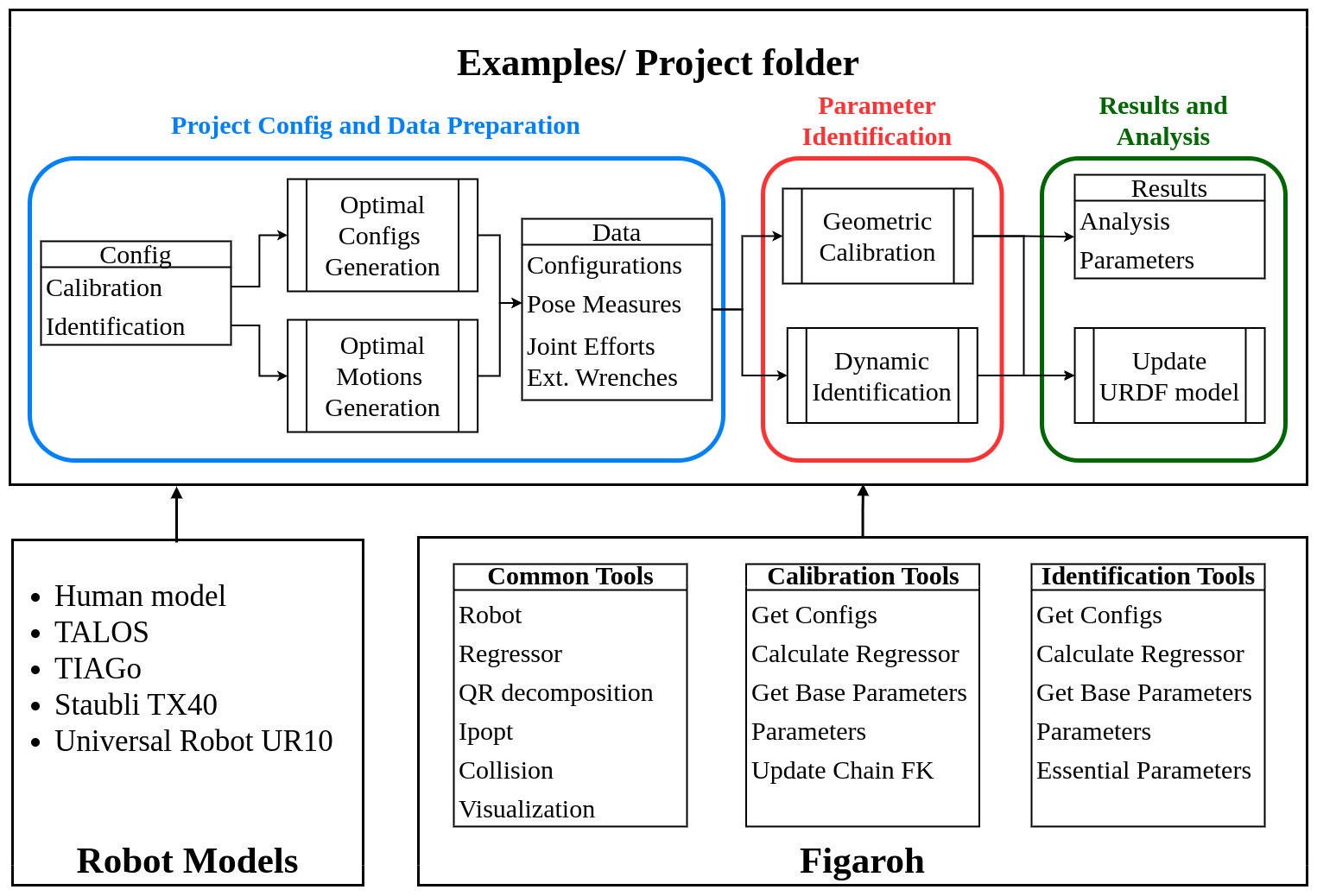

This paper presents a novel method for whole-body geometric calibration of humanoid robots using a single plane, embedded sensors, and an admittance controller, introducing the IROC algorithm for optimal posture selection that achieved 2.3x accuracy improvement on the TALOS robot.